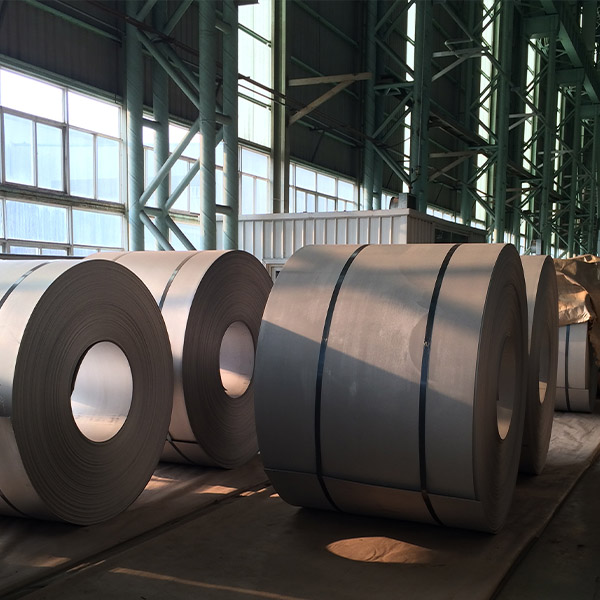

Pickling Hot Rolled Steel Coil

Ukuran piring baja kudu nyukupi syarat meja "Dimensi lan Spesifikasi Plat Baja Gulung Panas (Dipetik saka GB / T709-1988)".

Ukuran Strip baja kudu nyukupi syarat tabel "Dimensi lan Spesifikasi Strip Baja Gulung Panas (Dipetik saka GB / T709-1988)".

Jembaré piring baja bisa uga ukurane 50mm utawa kaping pirang-pirang 10mm.

Dawane piring baja yaiku ukuran 100mm utawa pirang-pirang 50mm, nanging dawa minimal piring baja kanthi ambane kurang saka utawa padha karo 4mm ora kudu kurang saka 1.2m, lan dawa minimal piring baja. kanthi kekandelan luwih saka 4mm kudu ora kurang saka 2m.

Miturut syarat, kekandelan saka piring baja kurang saka 30mm, interval kekandelan bisa 0.5mm.

Miturut kabutuhan, sawise rembugan antarane supplier lan panuku, piring baja lan ngudani ukuran liyane bisa diwenehake.

Ketebalan umum:0.8, 1.0, 1.2, 1.5, 1.8, 2.0, 2.35, 2.45, 2.50, 2.70, 2.75, 2.8, 2.9, 2.95, 3.0, 3.25, 3.3, 3.8, 3.3. 3.95, 4, 4.25, 4.5, 4.7, 4.75, 5, 5.5, 5.75, 6, 6.75, 7, 7.5, 7.75, 8, 8.75, 9, 9.5, 9.75, 10.

Rolling terus-terusan panas bisa dipérang dadi baja struktural karbon biasa, baja paduan rendah, lan baja paduan miturut materi lan kinerja. Miturut panggunaan sing beda, bisa dipérang dadi: baja kadhemen, baja struktural, baja struktur otomotif, baja struktur tahan karat, baja struktur mekanik, silinder gas sing dilas lan baja prau tekanan, baja pipa, lsp.

Unit piring panas-dip galvanis nganggo proses annealing Sendzimir sing luwih apik, lan bahan mentah yaiku gulungan pickled panas. Proses produksi kaya ing ngisor iki:

Hot-rolled pickled coil → uncoiling → cutting head and tail → welding → entrance looper → modified Sendzimir horisontal annealing furnace → hot-dip galvanizing → cooling after plating → zinc layer thickness gauge → smoothing and straightening → passivation treatment → Inspection table → Electrostatic oiling → Coiling → Timbangan lan pengepakan → Panyimpenan produk rampung.