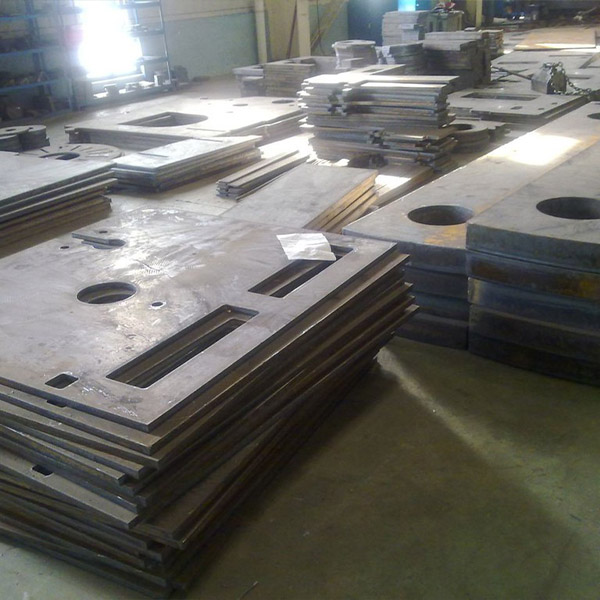

NM500 High-Kekuwatan Wear-Tahan Steel Plate

N minangka aksara pinyin pisanan saka "Nai" ing "Wear".

M minangka huruf pinyin pisanan saka "gilingan" ing "tahan nyandhang".

500 yaiku nilai kekerasan Brinell HB. (Nilai kekerasan 500 jembar, nilai kekerasan NM500 domestik kira-kira 500.)

Klasifikasi kelas:NM500ANM500B

Perawatan panas:nyenyet lan nyenyet (quenching + tempering).

Aplikasi:Plat baja tahan nyandhang NM500 akeh digunakake ing mesin teknik, mesin pertambangan, mesin pertambangan batu bara, mesin perlindungan lingkungan, mesin metalurgi, alat abrasif, bantalan lan bagean produk liyane.

Mesin konstruksi, mesin pertambangan, mesin pertambangan batu bara, mesin perlindungan lingkungan, mesin metalurgi lan perusahaan manufaktur liyane. Digunakake kanggo excavator, loader, buldoser piring ember, piring agul-agul, piring agul-agul sisih, glathi, crusher liners.

Gunakake piring nganggo:

1) Pembangkit listrik termal: medium-speed coal mill cylinder liner, fan impeller socket, dust collector inlet flue, ash duct, bucket turbine liner, separator connecting pipe, coal crusher liner, coal scuttle and crusher Machine liner, burner burner, coal fall hopper lan corong liner, kothak pangayoman krenjang preheater online, separator guide vane. Bagean ing ndhuwur ora nduweni syarat dhuwur babagan kekerasan lan tahan nyandhang saka piring baja tahan nyandhang, lan piring baja tahan nyandhang kanthi kekandelan 6-10mm ing materi NM360/400 bisa digunakake.

2) Coal yard: feeding trough lan hopper lining, hopper bushing, fan blades, pusher plate ngisor, siklon kolektor bledug, coke guide liner, ball mill lining, bor stabilizer, screw feeder lonceng lan basis Kursi, kneader bucket lining, ring feeder, dump truck piring ngisor. Lingkungan kerja ing lapangan batu bara atos, lan ana syarat tartamtu kanggo resistensi karat lan tahan nyandhang saka piring baja tahan nyandhang. Disaranake nggunakake piring baja tahan nyandhang NM400/450 HARDOX400 kanthi kekandelan 8-26mm.

3) Pabrik semen: lining chute, bushing pungkasan, kolektor bledug siklon, bilah pemisah wêdakakêna lan bilah panuntun, glathi penggemar lan lapisan, daur ulang ember lining, screw conveyor ngisor plate, komponen pipa, frit cooling plate Lining, ngaturake trough lining Papan. Bagean kasebut uga mbutuhake piring baja tahan nyandhang kanthi resistensi nyandhang lan tahan karat sing luwih apik, lan piring baja tahan nyandhang kanthi kekandelan 8-30mmd digawe saka NM360/400 HARDOX400 bisa digunakake.

4) Mesin loading: unloading mill chain plate, hopper liner, grab blade plate, dump truck dump board otomatis, dump truck body. Iki mbutuhake piring baja tahan nyandhang kanthi kekuatan lan kekerasan tahan nyandhang sing dhuwur banget. Disaranake nggunakake piring baja tahan nyandhang kanthi bahan NM500 HARDOX450/500 lan kekandelan 25-45MM.

5) Mesin pertambangan: linings, blades, conveyor linings lan baffles saka bahan mineral lan stone crushers. Bagean kasebut mbutuhake resistensi nyandhang sing dhuwur banget, lan materi sing kasedhiya yaiku NM450/500 HARDOX450/500 piring baja tahan nganggo kanthi kekandelan 10-30mm.

6) Mesin konstruksi: piring gigi pendorong semen, menara pencampur beton, piring lapisan mixer, piring lapisan kolektor debu, piring cetakan mesin bata. Disaranake nggunakake piring baja tahan nyandhang digawe saka NM360/400 kanthi kekandelan 10-30mm.

7) Mesin konstruksi: loader, buldoser, pelat ember excavator, pelat bilah sisi, pelat ngisor ember, bilah, rod pengeboran rig pengeboran rotary. Mesin jinis iki mbutuhake piring baja sing kuwat lan tahan nganggo kanthi kekuatan tahan nyandhang sing dhuwur banget. Bahan sing kasedhiya yaiku NM500 HARDOX500/550/600 pelat baja tahan aus kanthi kekuatan dhuwur kanthi kekandelan 20-60mm.

8) Mesin Metalurgi: mesin sintering bijih besi, siku conveying, liner mesin sintering bijih besi, liner scraper. Amarga mesin jinis iki mbutuhake piring baja tahan suhu sing dhuwur lan tahan banget. Mula, disaranake nggunakake piring baja tahan aus seri HARDOX600HARDOXHiTuf.

9) Wear-tahan piring baja uga bisa digunakake ing silinder pabrik wedhi, glathi, macem-macem yard barang, mesin terminal lan bagean liyane, prewangan bagean struktural, railway wheel struktural bagean, gulungan, etc.