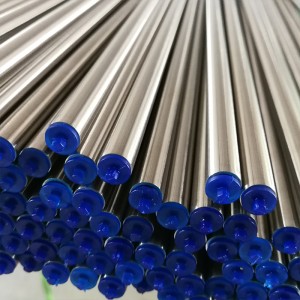

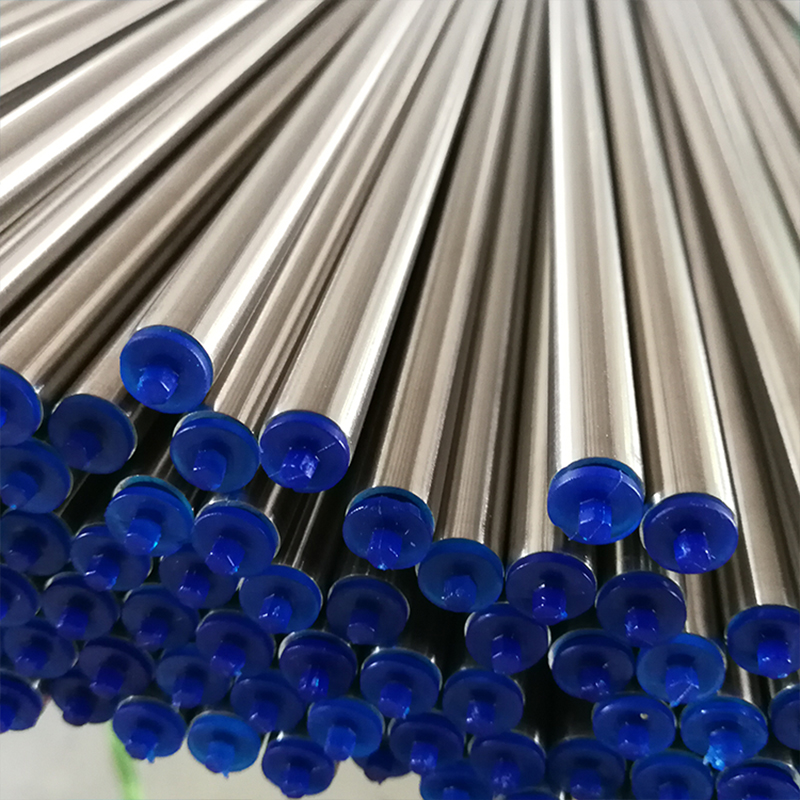

304 316 Pangilon Dipoles Pipa Stainless Steel Seamless

Standar: JIS

digawe ing China

Jeneng merek: Jinbaicheng

Model: 304 316 309S 316L 321

Tipe: Seamless steel

Kelas: 304 316 309S 316L 321, 316Ti, 316L, 316, 321, 304, Aplikasi, 3304L

Industri, jalur las pipa pupuk

Tipe: Seamless

Dhiameter njaba: 25.4mm

Toleransi: ± 1%

Layanan pangolahan: mlengkung, welding, uncoiling, punching, nglereni, mbentuk, kustomisasi

Kelas: 304 316 309S 316L 321

Bentuk bagean: bunder

Alloyed utawa ora: non-alloyed

Perawatan lumahing: BA

Invoice: Miturut bobot teoritis

Wektu pangiriman: 15-21 dina

Jeneng produk: 304 316 pangilon dipoles pipa/tabung stainless steel mulus

Wangun: bunder, kothak, persegi dowo

Teknologi: Hot mbalek lan kadhemen digambar

Lumahing: padhang / dipilih / polesan

Syarat pembayaran: 30% TT Advance + 70% Balance Price Term: CIF CFR FOB EX-WORK MOQ: 1 ton

Kemasan: Kemasan standar udara

Sampel: gratis

Persediaan: akeh

Sertifikasi: BV

Kemampuan Penyetor: 10.000 ton / ton saben wulan

Rincian packing: packing biasa

Pelabuhan: Shanghai Tina Jingua Hangzhou Qingdao

| Tabel spesifikasi pipa stainless steel | ||

| Spesifikasi | Spesifikasi | Spesifikasi |

| 6-12×1.5-2.5 | 73×4-4.5-5-6-7-8-9-10-12-15 | 219×30-40 |

| 14×1.5-2.5-3 | 76×4-4.5-5-6-7-8-9-10-12-14 | 245×8-10-14-17-20-22 |

| 16×1.5-2.5-4 | 83×4.5-5-10 | 245×25-28-30-34-40 |

| 18×2.3-4-5 | 89×4.5-8-10 | 273×7-9-12-15-18-20-25 |

| 20×2.5-3-5 | 95×4.5-6-8 | 273×30-35-38-40 |

| 24×2.5-3-4-5-6 | 102×4.5-5-6-10-12-14-16-20 | 299×8-12-16-20-24-28 |

| 25×2.5-3-4-5-6 | 108×4.5-5-14-18-20-22 | 299×30-32-36-38-40 |

| 28×3-3.5-4-5-6 | 114×4.5-5-6-7-8-10-12-14-18-20 | 325×8-12-14-18-38 |

| 32×3.5-4-5-6-8 | 121×4.5-5-6-7-8-10-12-14-16-20 | 325×28-32-34-38 |

| 34×4-5-6-8 | 127×4.5-5-6-7-8-10-12-14-16-20 | 351×10-16-20-25-40 |

| 36×3.5-5-6-8 | 133×4.5-6-8-12-14-16-18-20-25-30 | 355×6-18-20-25-30-40 |

| 38×4-5-6-7-8-9-10 | 140×5-6-7-8-9 | 377×8-12-15-20-24-28 |

| 39×3.5-5-8-10 | 146×4.5-6-8 | 377×30-37-40 |

| 42×3.5-4-5-6-7-8-9-10 | 152×4.5-6- | 402×10-20-25-30-35 |

| 45×3.5-4-5-6-7-8-9 | 159×4.5-6-10-12-14 | 406×10 |

| 48×3.5-4-5-6-7-8-9-10 | 159×16-18 | 426×10 |

| 51×3.5-4-5-6-7-8-9-10 | 168×8-25-30-35 | 450×10-20-25-34-40 |

| 56×3.5-4-5-6-7-8-9-10 | 180×8-12-16-25-30 | 480×25-30-40 |

| 57×3.5-5-6-7-8-9-10-12 | 180×32-34-38-40 | 500×10-34-40-45 |

| 60×3.5-4.5-5-6-7-8-9-12-14 | 194×6-8-25-30-40 | 510×10-25-34-40-45 |

| 63×3.5-4.5-5-6-7-8-9-10-12-14 | 203×6-7-10-15-20-25-30 | 530×20-30-40 |

| 68×4-4.5-5-6-7-8-9-10-12-14-16 | 203×32-36-40 | 560-720*6-10-24-45 |

| 70×4-4.5-5-6-7-8-9-10-12-15-16 | 219×6-8-12-16-18-20-25 | |

| sasmita | C | Si | Mn | P | S | Ni | Cr | Mo | Cu |

| SUS304 | ≤0.08 | ≤1.00 | ≤2.00 | ≤0,045 | ≤0,030 | 8.0-10.0 | 18/20 | -- | -- |

| SUS301 | ≤0.15 | ≤1.00 | ≤2.00 | ≤0,045 | ≤0,030 | 6.0-8.0 | 16/18 | -- | -- |

| SUS201 | ≤0.15 | ≤0,75 | ≤5.5/7.5 | ≤0.06 | ≤0,030 | 0.8-1.2 | 16/18 | -- | -- |

| SUS430 | ≤0.12 | ≤0,750 | ≤1.00 | ≤0,040 | ≤0,030 | ≤0,60 | 16/18 | -- | -- |

| SUS443 | ≤0,015 | ≤1.00 | ≤1.00 | ≤0.04 | ≤0,030 | -- | ≥20 | -- | ≤0.3 |

| SUS310S | ≤0.1 | ≤1,50 | ≤2.00 | ≤0,045 | ≤0.03 | 19-22 | 24-26 | -- | |

| SUS316L | ≤0,07 | ≤1.00 | ≤2.00 | ≤0,045 | ≤0.30 | 10-14 | 16-18.5 | 2.0-3.0 | -- |

Proses produksi pipa stainless steel mulus:

a. Persiapan baja bunder;

b. dadi panas;

c. perforasi digulung panas;

d. Cut sirah

e. Pickling

f. mecah

g. lubricating;

h. Gulung kadhemen

i. Degreasing

j. Solusi perawatan panas;

k. Lurus

l. Cut tabung

m. Pickling

n. Pengujian produk.

Industri Otomotif

Stainless steel utamané dipigunakaké ing sistem exhaust, kang akun kanggo luwih saka 1/2 saka jumlah total stainless steel otomotif, lan 80% punika stainless steel ferritic. Gas buang sing diasilake mesin mobil pungkasane mili metu saka knalpot liwat pipa intake gas exhaust, pipa ngarep, selang, konverter, lan pipa tengah. Kelas baja sing umum digunakake kanggo sistem knalpot yaiku 409L, 436L, lsp. Muffler mobil utamane nggunakake pipa las stainless steel. Miturut prakiraan, pipa stainless steel sing digunakake ing mobil kira-kira 1,5% saka konsumsi hilir pipa stainless steel, lan rasio panggunaan pipa stainless steel lan pipa sing dilas kira-kira 2:1.

Industri petrokimia kalebu industri pupuk

Ana panjaluk gedhe kanggo pipa stainless steel. Industri utamane nggunakake pipa baja stainless steel. Spesifikasi kalebu: 304, 321, 316, 316L, 347, 317L, lan sapiturute. Dhiameter njaba kira-kira 18-610, lan kekandelan tembok 6mm-50mm Around (biasane pilih medium lan low pressure conveying pipes kanthi spesifikasi ing ndhuwur. Φ159mm), area aplikasi khusus yaiku: pipa tungku, pipa pengantar material, pipa penukar panas, lsp.

Transportasi cairan kayata banyu lan gas

Pipa baja tahan karat lan peralatan pangiriman banyu minangka bahan pemurnian banyu dhasar sing paling maju ing donya saiki. Dheweke duwe resistensi karat sing kuwat lan ora bisa dibandhingake karo pipa wesi, pipa baja karbon, lan pipa plastik.

Pilihan sing paling apik kanggo industri banyu kayata nyiapake banyu, panyimpenan, transportasi, pemurnian, regenerasi, lan desalinasi. Panjaluk taunan kira-kira 25.000 ton.

Manufaktur lan pangopènan peralatan

Konsumsi taunan pipa stainless steel luwih saka 20.000 ton. Industri jinis iki utamane nggunakake pipa baja tahan karat sanitasi utawa antibakteri. Pipa mulus sanitasi sing digawe saka SUS304 lan 316L sing diimpor bisa nyukupi syarat khusus saka macem-macem media ing bidang pangan lan biofarmasi. Baja tahan karat antibakteri nduweni kaluwihan baja tahan karat lan sifat antibakteri sing apik. Panjaluk peralatan pawon, meja kerja lan peralatan ing industri panganan, peralatan medis, peralatan meja lan andhuk ing saben dinane, lan kurung kanggo lemari kulkas saya tambah.